Our business was established with a view to provide services of Diesel Engine Reconditioning

and General Heavy machining. Also, our core business is of Whitemetal Lining of bearings, using our self developed method of centrifugal lining of worn out bearings, upto 1.5 meters in diameter.

In the course of our activities our business moved into supporting the needs of the ship repair industry and land based factories/plants in and around Mumbai.

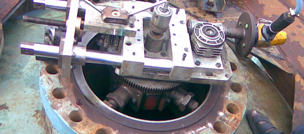

We began machining of large components for ships, and routinely serviced CPP propeller hub, main engine crankcase line boring in-situ, shaft alignment and stern tube bearing recon and fitment, rudder stock machining, rudder housing bore machining. Drilling / reaming of rudder fit-bolts, Turbine casing boring.

Our expertise in the basics of machining and high level of understanding in the accuracies required, led us to offer in-situ machining services that are typically designed on a ‘per job’ basis.

Every in-situ machining job has it’s own intricacies and demands, we design and develop equipment to suit the machining needs of a particular job.

Our capabilities have allowed us to successfully conduct in-situ machining operations for marine as well as land based industries.

All it takes is one call from the client and we mobilize our team to make an assessment of the job. Our response is among the fastest in the industry, our machine-design ability can take on any challenge that arises. On call, 24 hours—9820072045.

“If we say it can be done………….it will be done---no matter what the challenge!”

Regards,

Girish Singh.

In the course of our activities our business moved into supporting the needs of the ship repair industry and land based factories/plants in and around Mumbai.

We began machining of large components for ships, and routinely serviced CPP propeller hub, main engine crankcase line boring in-situ, shaft alignment and stern tube bearing recon and fitment, rudder stock machining, rudder housing bore machining. Drilling / reaming of rudder fit-bolts, Turbine casing boring.

Our expertise in the basics of machining and high level of understanding in the accuracies required, led us to offer in-situ machining services that are typically designed on a ‘per job’ basis.

Every in-situ machining job has it’s own intricacies and demands, we design and develop equipment to suit the machining needs of a particular job.

Our capabilities have allowed us to successfully conduct in-situ machining operations for marine as well as land based industries.

All it takes is one call from the client and we mobilize our team to make an assessment of the job. Our response is among the fastest in the industry, our machine-design ability can take on any challenge that arises. On call, 24 hours—9820072045.

“If we say it can be done………….it will be done---no matter what the challenge!”

Regards,

Girish Singh.

Facilities and Machinery Installed:

- Horizontal Boring 100mm Bragonzi – Italy

- Crankshaft Grinding 2000mm AMC Denmark.

- Vertical Boring Van Norman USA 3nos.

- Center Lathes 1000mm to 3500mm 4 nos.

- Universal milling machine- 1 no.

- Vertical pillar drills 2 nos.

- Cylinder head recon equipment SIOUX USA.

- Line boring machine: 4500mm

- Hydraulic press 100 tons

- Overhead cranes 2 nos. 10 tons

- Welding rectifiers 400Amps 2 nos.

- White Metal lining centrifugal machine. 1500mmDia.

- White Metal Melting Equipment: 500Kg.

- Connecting Rod Boring. Delapena England 700mm.

- Honing Machine 200mm x 1000mm

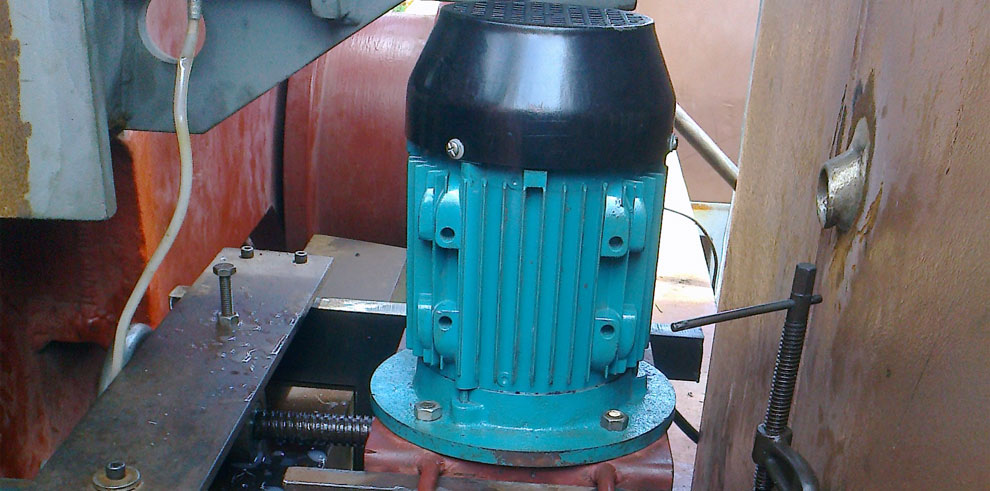

- Portable/In-Situ Machining Equipment: a)Flange Facing b)Line boring c)Drilling d)Boring e)Milling etc.

- Measuring Equipment: Micrometers, Bore Gauges upto 1000mm

»

»