Driling

CONFINED DRILLING AND BORING

We were approached by a leading ship builder to Drill And Bore the Guide Rail for Locking Pins of Ships’ Hatch Cover.

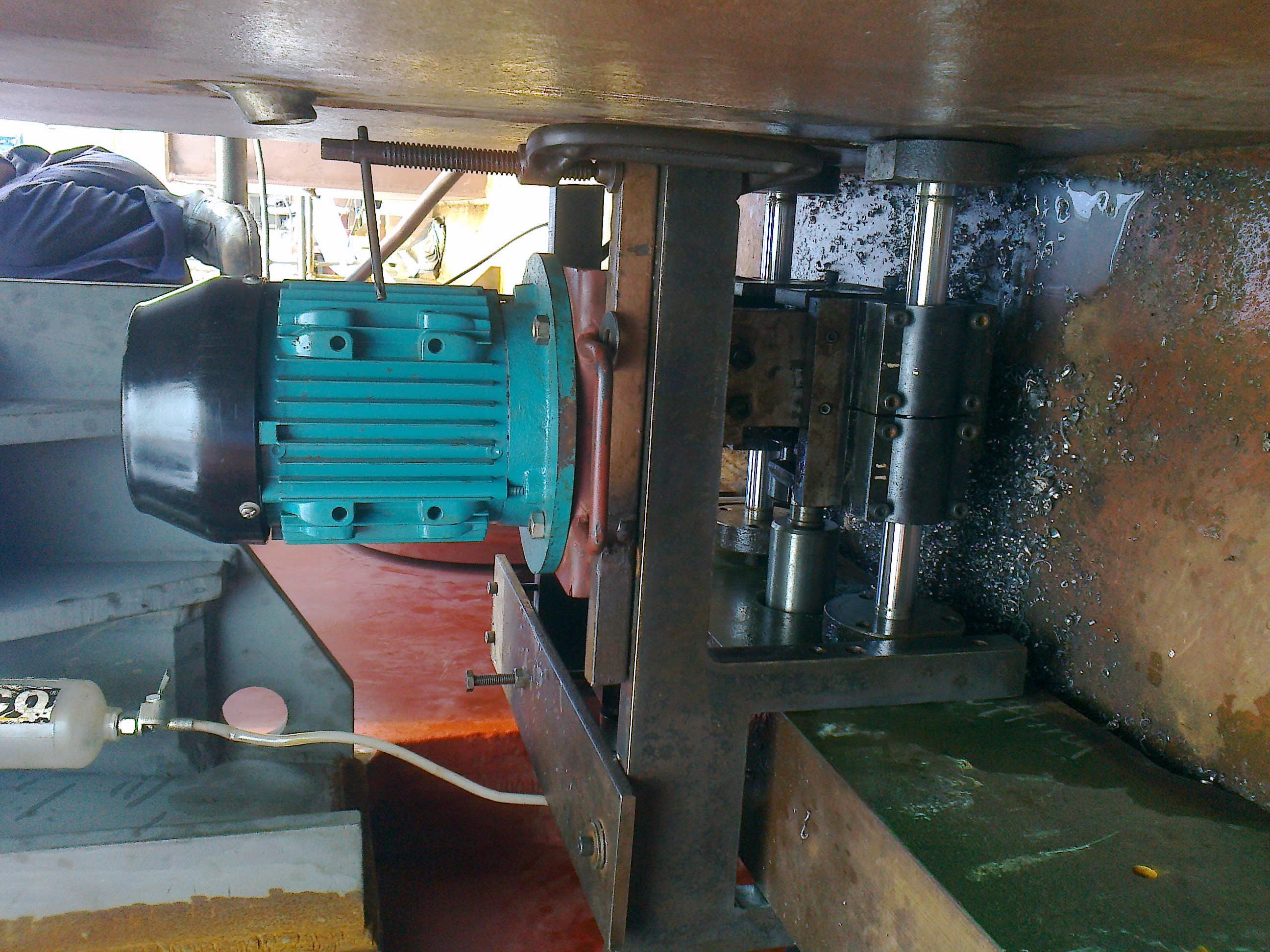

The location of the holes was extremely confined and NO existing drilling or boring equipment could be found to undertake the job.

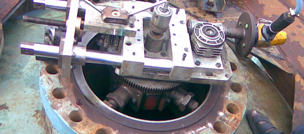

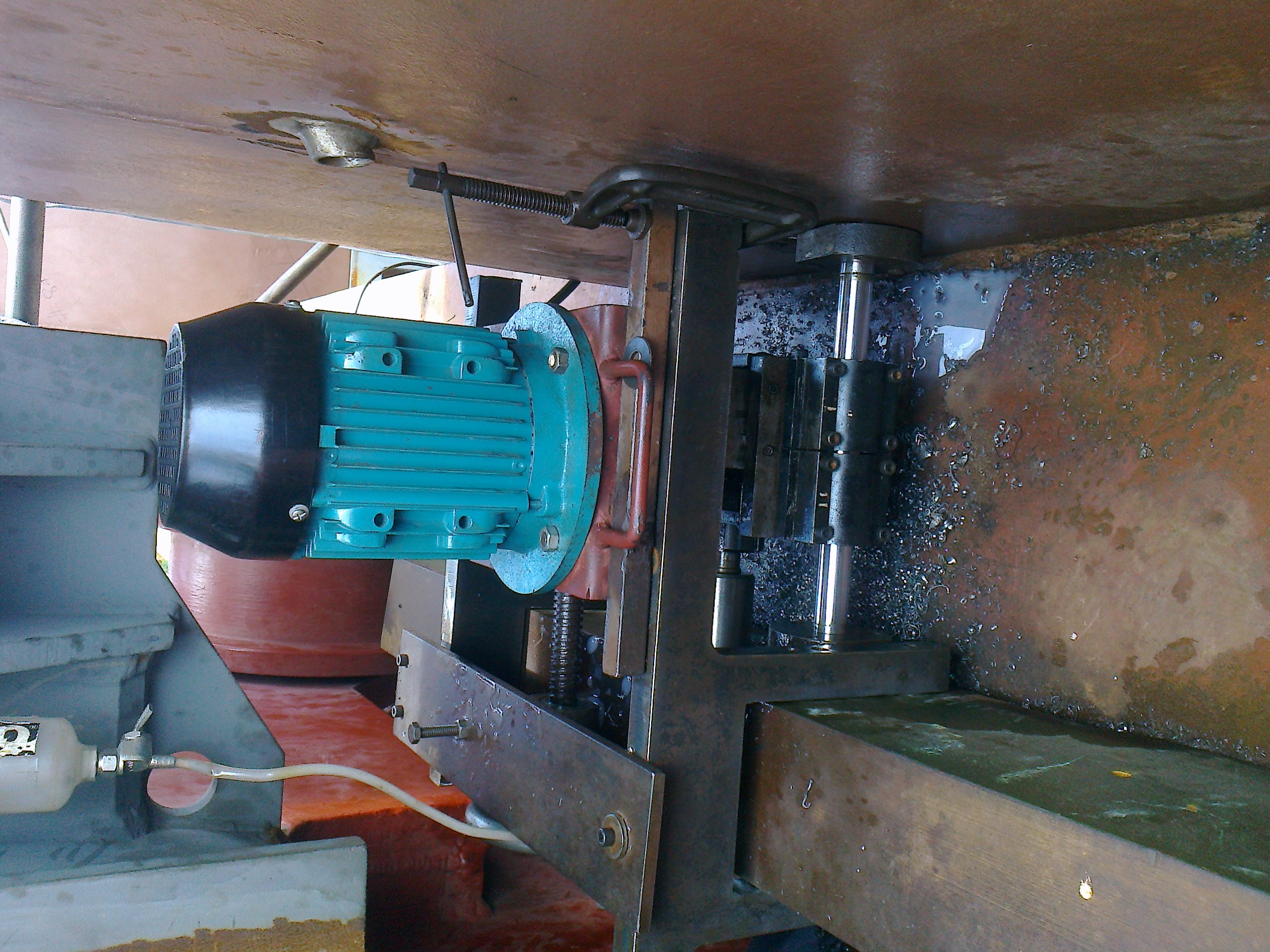

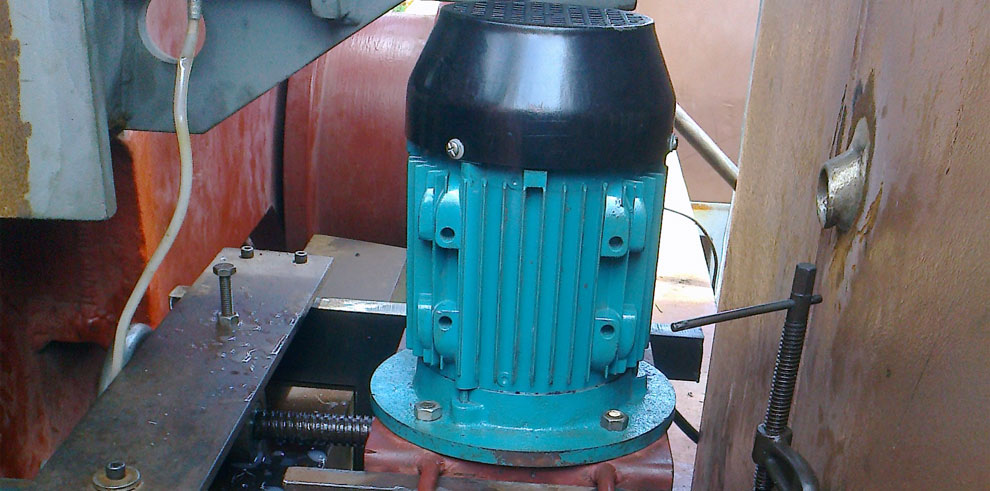

Ready to accept this challenging job we set about designing the machine and equipment.

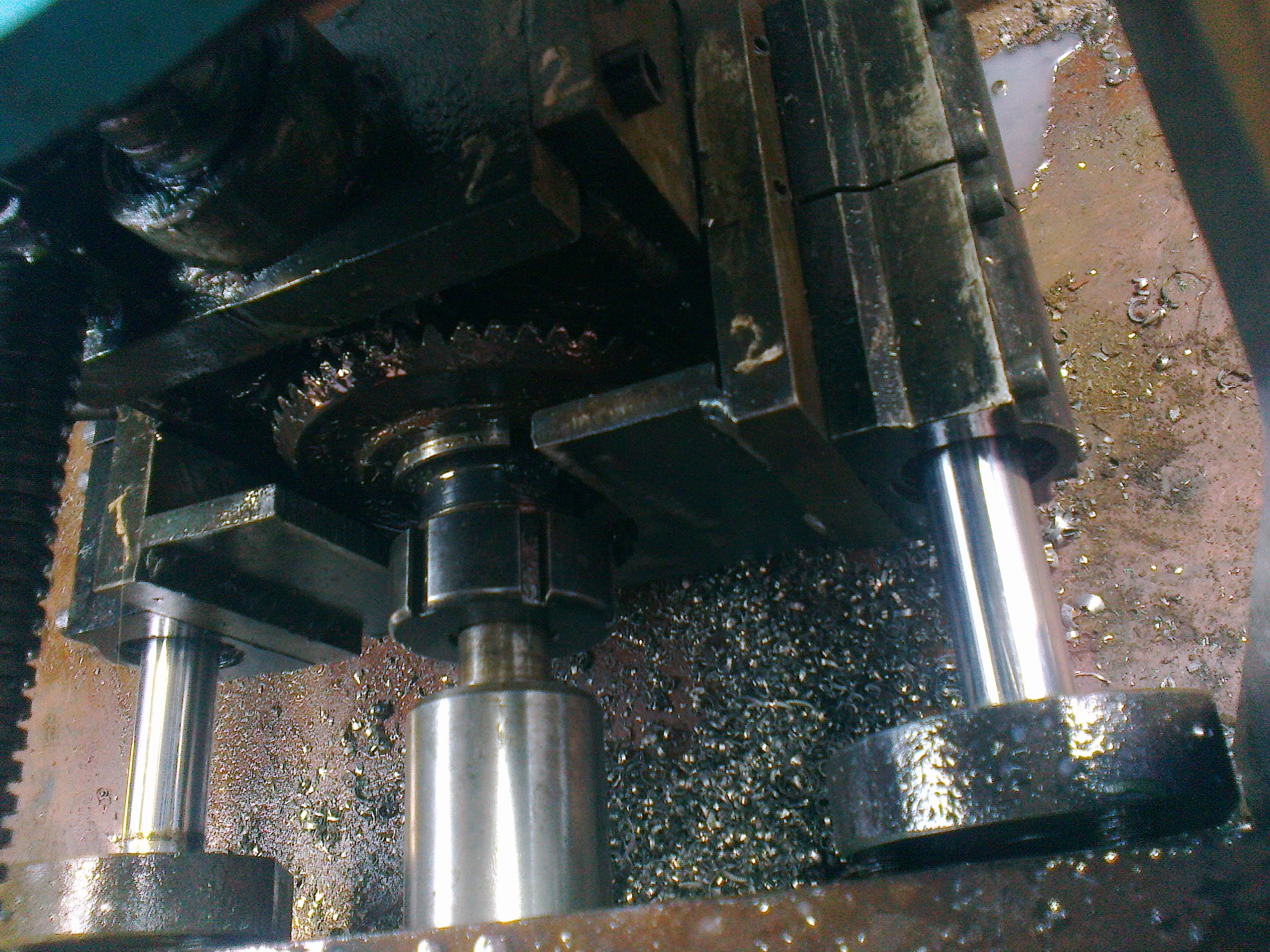

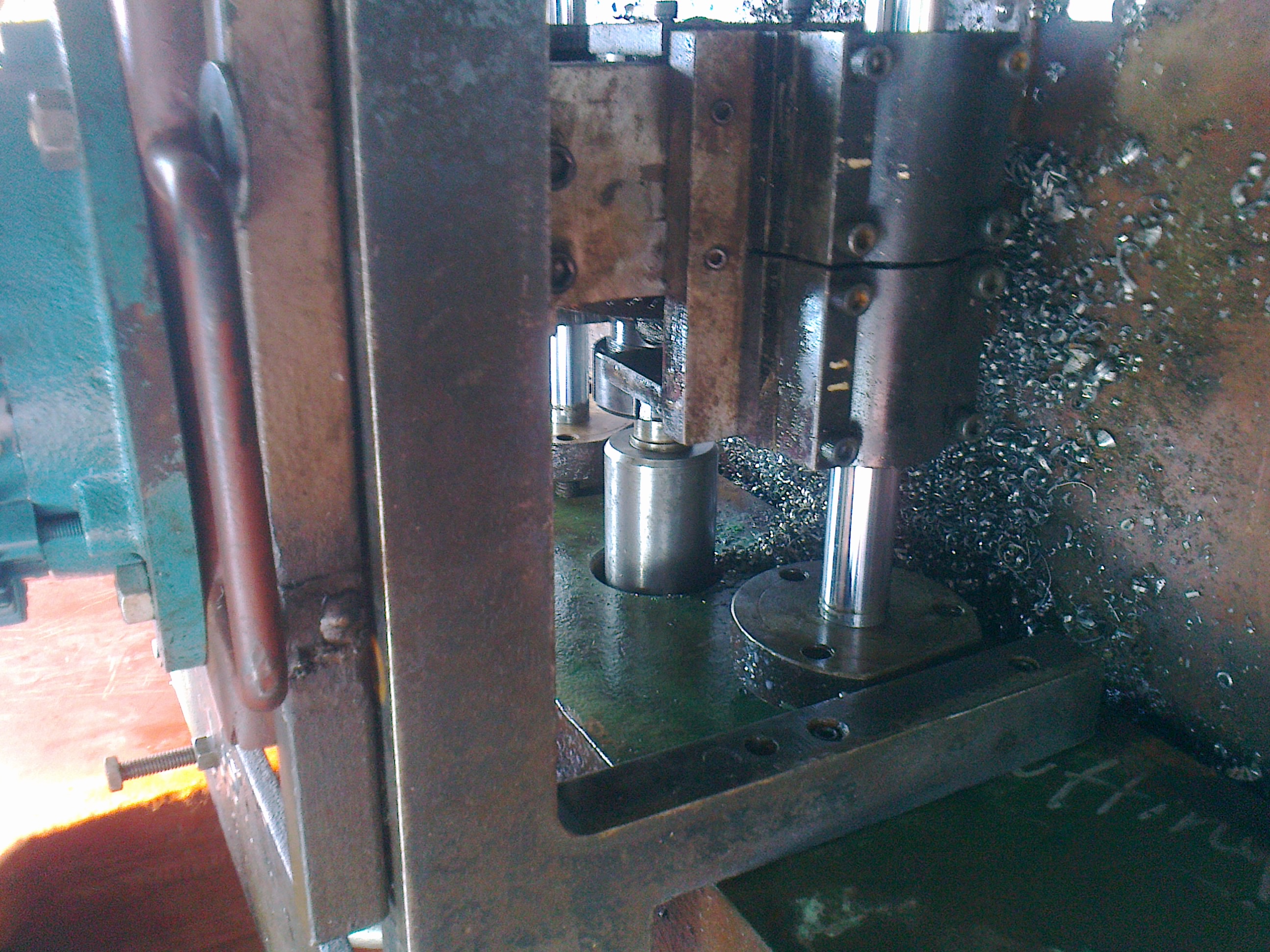

We designed and developed drilling & boring machine’s to drill into the Guide Rail upto a bore sizes of 92mm, 120mm thru.

Our method of sequential drilling and boring, proved to be a great success and we managed the entire work without spillage of cutting fluids and maintained general cleanliness during the work on board this newly built ship.

The available space to install our equipment and machine was only 300mm!

We successfully carried out the job, & achieved the design accuracy, in quick time.

This challenging job was greatly appreciated by the client.

»

»